The ArtCut CNC Flame/Plasma Cutting Machine is a flexible all-round system that is very cost effective, and by combining oxy-fuel cutting and plasma cutting processes this system provides users with productivity improvements and cost saving benefits.

This single machine is suitable for gas cutting of carbon steel in 5-300 mm thickness range, and can support plasma cutting for stainless steel, carbon steel and non-ferrous metal in 0.5-160 mm thickness range (depending on capacity of plasma source selected). The rack & pinion drive mechanism employs a reliable brush-less AC servo system with precision planetary gearboxes for high positional accuracy, and linear guides for smooth, accurate motion of the torches in the cross axis.

Heavy duty rail is machined and surface treated for long life and smooth motion. Each oxy-fuel torch is mounted to a robust motorized lifter, using a ball-screw mechanism and linear guides to insure the up/down movement is accurate and true. Automatic flame ignition and automatic capacitive torch height control systems offered to fully automate the cutting process and insure the cut quality is consistently high. Plasma torch petitioners all have built in 360° anti-collision devices to protect the torch from damage. Several options for arc voltage torch height control are offered so the most suitable system can be selected to match the type of plasma cutting system required for the user application.

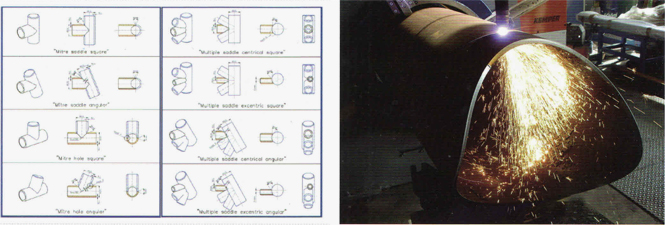

The Art CUT is offered with a choice of user friendly CNO controls, and by using our nesting software to prepare cutting programs the user can optimize plate utilization and consistently produce high quality cut parts!

| Type | Parameter | |

| ArtPcut Pipeline Transversal CNC Flame/Plasma Cutting Machine | ||

| Pipe Diameter Range | Φ 60 - Φ 1000mm | Φ 1000 - Φ 2000mm |

| Maximum weight of pipe | 20000KG | 45000KG |

| Flame cutting torch | 1 set | |

| Plasma Torch | Optional | |

| Cutting the workpiece material | Carbon steel, Stainless stee, Alloy steel, nonferrous metals etc. | |

| Vertical speed | 10000mm/min | |

| Cutting speed | 100-3000mm/min | |

| Flame cutting thickness | 5-60mm | |

| CNC axes | 2-6 (according to customer requirement) | |

| Pipe rotation axis | Unlimited rotation | |

| Elliptical Compensation, Dynamic Torch Height Control | Real-time measurenent of pipe roundness, dynamic elliptical compensation ensuies consistent height between cutting nozzle, and the pipe surface, preventing collision of the pipe surface with torch tip | |

| Cutting torch up and down movements | 150-550mm | 550-1100mm |

| Torch from side to side | ±60° | |

| Torch back and forth | ±50° | |

| Cutting nozzle expansion | 50mm | |

| Minimum crossing angle | 20 | |

| Chuck clamping jaws | 3-4 | |

| Chuck hole diameter | 190 mm or 260 mm | |

| Electric chuck | Optional | |

| Pipe Support Brackets | 4 Sets (or as per request of Customer) | |

| Acceptable ambient temperature | -5°C— 50°C | |

| Cutting mode | Oxygen + Acetylene, Oxygen + Propane, or Plasma | |

| Power supply voltage | 380V 50HZ | |